Up To Date Laundry Switches to Low NOx Boilers

Cleaning over 1 million pounds of laundry per week requires a significant amount of energy and reliable steam on demand. That’s why, as part of their green initiative to reduce their carbon footprint, Up To Date Laundry chose to replace their two conventional 300-HP fire tube boilers with three compact Miura LX-200 boilers.

As a result of this switch, not only has the company seen a tremendous reduction in their CO2 and NOx emissions, but they are also on track to see their energy costs lowered by 20 percent or more annually.

DOWNLOAD THE FULL CASE STUDY

“Miura boilers heat up quicker, provide steam more steadily, and deliver more versatility,” says Ken Weiman, Up To Date Laundry’s Chief Engineer. “They provide a tremendous amount of efficiency. For such a small boiler to put out such a large volume of steam so rapidly, on-demand, is incredible. During a break or if there is a rapid falloff, the boilers take care of themselves. They will either shut down or go to low fire on a standby system.”

Precision Monitoring and Self-Diagnostic Features

Another feature that Up To Date finds beneficial about their Miura boilers is their self-diagnostic capability (via an onboard BL Micro Controller) and remote monitoring (via Miura Online Maintenance). The units have a “sliding-window” feature that enables them to record issues four seconds before they occur, hastening the troubleshooting process and reducing the risk of breakdowns and downtime. “I can watch the boilers and see what they’re doing from my desk,” says Weiman. “I know where I am at with my fuel and I know what my BTU hours are; everything is right here for me. If there is a problem, if it needs a blow down I don’t have to check, it tells me.”

Additional Savings

Between Miura’s increased efficiency and advanced monitoring capabilities, Up To Date is seeing reduced costs not only in energy output, but also in labor costs. “I don’t have to have someone here all night watching them on low fire,” says Weiman. “With a simple push of a button they are off, and with another simple push of a button they are on again. Just with fuel savings and manpower savings alone, we shave several hours off each day.

“We are totally happy with our Miura boilers,” Weiman adds. “With Miura boilers, we don’t have a complaint in the world.”

DOWNLOAD THE FULL CASE STUDY

To learn more about Miura boilers, contact us today at 1-855-817-3722 or locate a Miura rep in your area.

Press Release

Premiere Provider of Laundry Services Relies on Miura LX-200 Boilers for Energy Savings and Efficiency

ATLANTA, February 11, 2014 – Founded in 1946, Up To Date Laundry services more than one million pounds of laundry per week for the healthcare and hotel industries in the Mid-Atlantic Region. Committed to Green principles of energy conservation and sustainability, Up To Date Laundry emphasizes that “The Future is Not Disposable” and employs multiple methods to reduce its carbon footprint. Among these many initiatives is the company’s use of three LX-200 natural gas-fired boilers made by Miura, the world leader in ultra-low NOx modular on-demand steam solutions.

“Miura boilers heat up quicker, provide steam more steadily, and deliver more versatility,” explains Ken Weiman, Chief Engineer of Up To Date Laundry. “The steam is used in heating water; also all of the ironers and presses are heated with steam as well as some of the dryers.”

Miura boilers are microprocessor-controlled for precision operation, and employ a unique “once-through” fin-tube design that heats a smaller volume of water more efficiently than other boilers. This design enables Miura boilers to generate full steam from a cold start in five minutes or less. (Weiman notes that Up to Date’s Miura boilers enable the entire plant to be at a working pressure of 125psi in under ten minutes.) This on-demand steam capability enables Miura boilers to be turned on or off as needed to efficiently manage changing load conditions, as opposed to idling in stand-by and consuming energy. The combination of microprocessor-control technology and on-demand steam also conserves fuel, saving an average of 20 percent annually on energy costs over other boiler designs for typical installations.

“Miura boilers provide a tremendous amount of efficiency,” noted Weiman. “For such a small boiler to put out such a large volume of steam so rapidly, on-demand, is incredible. During a break or if there is a rapid falloff, the boilers take care of themselves. They will either shut down or go to low fire on a standby system. I don’t have to have someone here all night watching them on low fire. With a simple push of a button they are off, and with another simple push of a button they are on again. Just with fuel savings and manpower savings alone we shave several hours off each day.”

Energy Savings

In addition to the on-demand steam and energy-conservation benefits of Miura boilers – as compared to conventional boilers – Miura also outputs reduced levels of nitrogen oxides (NOx), a major contributor to air pollution, as well as carbon dioxide (CO2), the most prevalent of greenhouse gases. Miura boilers achieve low-NOx performance by reducing the temperature of the boiler’s flame, which in turn reduces the amount of excited nitrogen atoms available to bond with oxygen to form nitrogen oxides. As a result of this, NOx emissions are reduced to around one-quarter of what traditional fire-tube boilers emit. This enables Miura boilers to comply with even the most stringent air-quality regulations. With regard to reduced CO2 emissions, Miura’s technology leverages superior operating efficiency to contribute significant carbon abatement with a payback.

“You’re not burning a lot of fuel, you’re not depending on slow boil; it’s rapid,” Weiman says. “If you came off of a break with our previous boilers and had a large demand, the next thing you knew you were trying to catch up; you lose your steam, steam pressure goes down, and as a result the machinery shuts down. With Miura we are also using less water. Anything you can save nowadays is a plus. It’s not an option, it’s a necessity.”

Smaller and More Precise

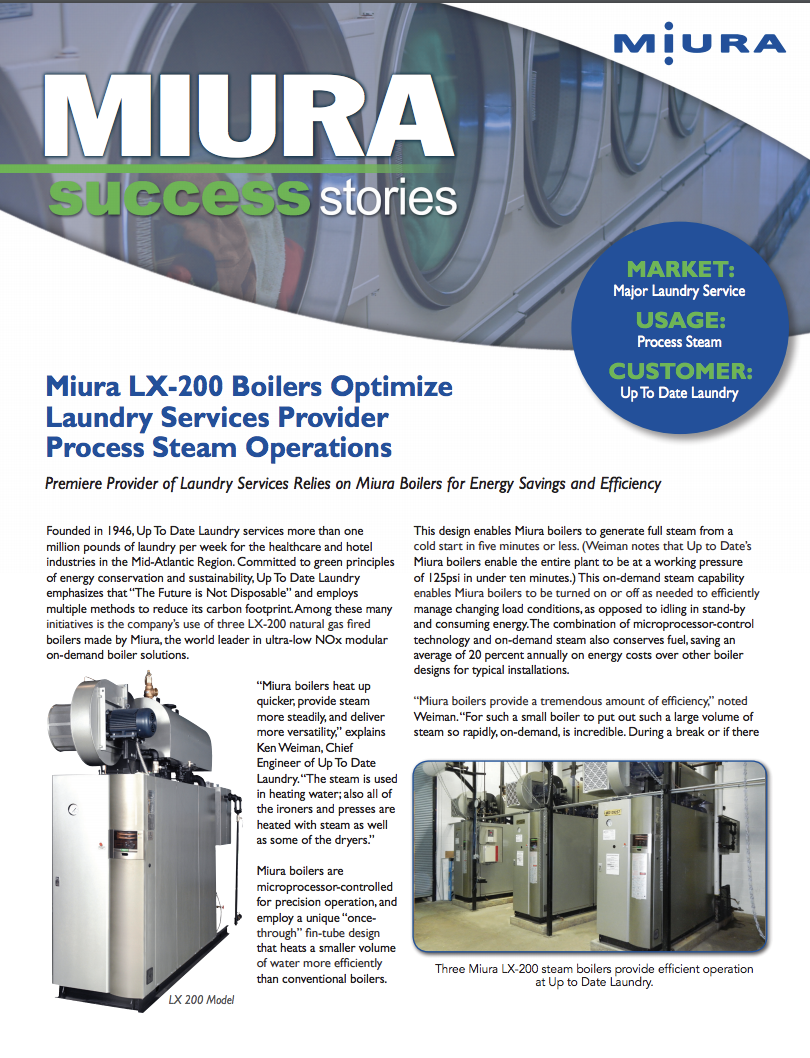

Prior to the purchase of their LX-200 boilers, Up To Date Laundry owned two 300 horsepower fire-tube boilers in their 70,000 square foot plant. Since their removal, a small room was built in their place that houses all three Miura boilers. “We created a complete boiler room so everything is self-contained in one room instead of two big boilers sitting in the middle of a maintenance shop,” Weiman explains. “From a safety perspective, anything pertaining to the boilers is in the boiler room.”

In addition to a compact footprint, high-energy efficiency, low emissions, and on-demand steam, every Miura boiler also features the BL Micro Controller, precision microprocessor-control technology that keeps track of multiple individual monitoring points. An advanced diagnostic system, it can identify any potential challenge to smooth operation and recommend a solution on an easy-to-read display. A “sliding-window feature” records events four seconds before they occur for fast and effective trouble-shooting. This system can also be accessed via the Internet using the Miura Online Maintenance (“MOM”) feature for remote monitoring and diagnostics. Miura owners are able to obtain regular performance data for extremely accurate tracking of all boiler performance parameters.

“Miura dials-in remotely as well, they are constantly on the ball,” Weiman notes. “I can watch the boilers and see what they’re doing from my desk. I know where I am at with my fuel and I know what my BTU hours are; everything is right here for me. If there is a problem, if it needs a blow down I don’t have to check, it tells me.”

The Miura MOM system can also interface with Miura’s Colormetry feature, which monitors water quality to prevent the build-up of scale inside the boiler. Another option is Miura’s Economizer package, an energy-saving component that works as a heat exchanger to capture and re-use heat from the boilers’ hot stack gas. Up to Date Laundry is among the many Miura users that have opted to use Miura’s BOILERMATE® water-treatment chemicals, the main ingredient of which is silicate, an environmentally friendly corrosion inhibitor.

“We are totally happy with our Miura boilers,” Weiman affirms. “Miura boilers are relatively new in the market, and people see them and say, ‘How do boilers that small provide so many advantages?’ I just tell them, ‘They do!’ With Miura boilers, we don’t have a complaint in the world.”

About Miura America Co., Ltd.

Miura Boiler was founded in 1927 and has grown to become one of the largest industrial steam boiler manufacturers in the world. In 2009, Miura opened a new U.S. manufacturing facility in Polk County, Georgia. For more information on Miura, call in the USA 1-855-874-8361. In Canada call 1-800-666-2182. Visit Miura online at: miuraboiler.com